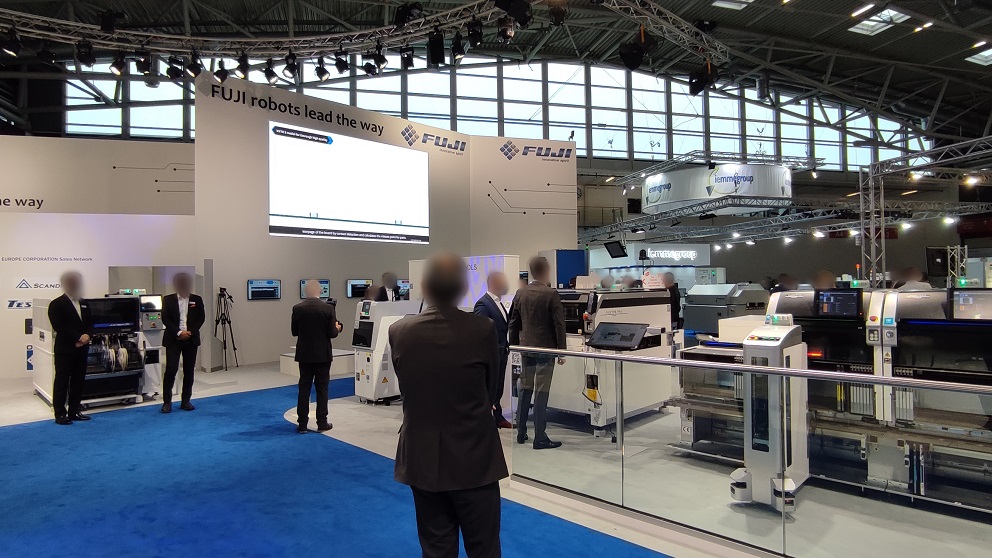

Fuji exhibited at the productronica 2021 event being held in Munich, Germany from November 16th (Tuesday) to the 19th (Friday). This event ended a success and we would like to express our heartfelt gratitude to those who helped make this happen.

The feedback that we received from everyone who came is greatly appreciated. The support that you give us is what allows us to continue to strive toward products and services that exceed expectations. We look forward to seeing you at future events.

On the exhibition floor

Movie

Fuji Smart Factory Solutions

Highlights

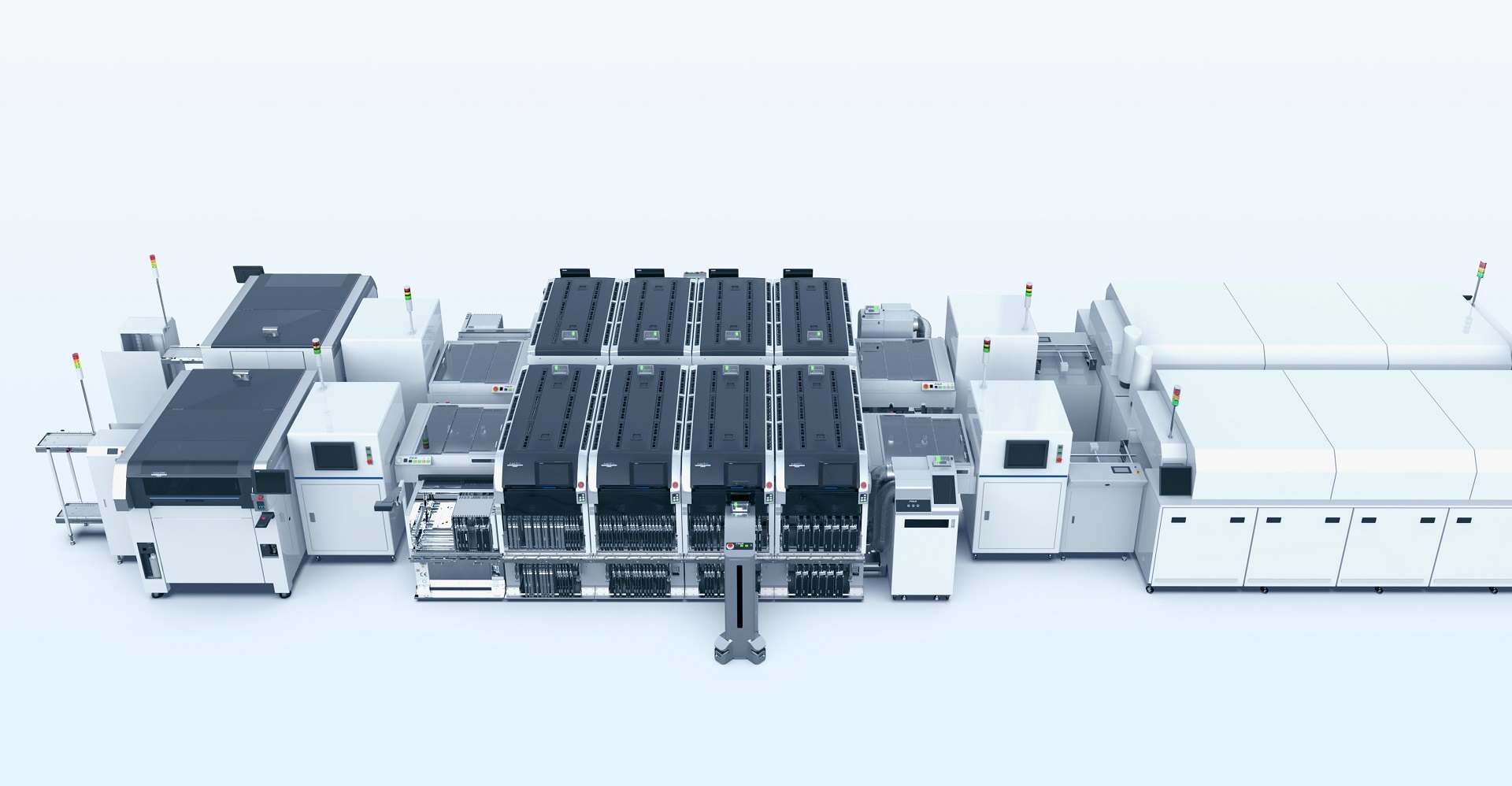

Fuji is working toward achieving digital twin technologies that eliminate the gap between the production plan (virtual) and actual results (real) through automation and digitalization centered on our latest placement solutions using NXTR and NXTR PM.

NXTR A model

The NXTR A model includes an automatic feeder exchange system that frees operators from changeover and supply work, with additional features that strengthen the ability to maintain high-quality and productivity.

Fuji is paving the way to the future of Smart Factories with NXTR.

Fuji is paving the way to the future of Smart Factories with NXTR.

NXTR S model

The NXTR S model offers a truly modular design for the optimal line configuration that caters to your production.

Real-time sensing placement, optimized placement actions, and part handling checks after placement are just a few examples. This high-end model machine from the NXT series supports new functions that preserve a high level of QCD performance.

Real-time sensing placement, optimized placement actions, and part handling checks after placement are just a few examples. This high-end model machine from the NXT series supports new functions that preserve a high level of QCD performance.

NXTR PM

NXTR PM is a printer that embodies the NXTR concept of reducing line size, high area productivity, front operation, and ease of use.

It is built to support wide panel and frame sizes, and has the capability to print delicate solder patterns.

It is built to support wide panel and frame sizes, and has the capability to print delicate solder patterns.

Auto Head Cleaner R

The Auto Head Cleaner automates head maintenance work, which requires experience and skill to perform manually. It thoroughly removes any dirt that has accumulated in the air routes inside heads, and also performs inspection afterwards. The maintenance history and inspection results are automatically registered to the system.

Smart Nozzle Cleaner

Periodic maintenance for nozzles, which could directly affect placement quality, is vital.

Smart Nozzle Cleaner does not just clean nozzles, it also performs inspection for items that are difficult to inspect using visual checks by operators. The maintenance history and inspection results are automatically registered to the system.

Smart Nozzle Cleaner does not just clean nozzles, it also performs inspection for items that are difficult to inspect using visual checks by operators. The maintenance history and inspection results are automatically registered to the system.

AIMEX IIIc

This is an all-in-on machine with scalability and the ultimate level of versatility necessary for increasing productivity for high-mix production. It features functions for performing operation smoothly in a short time for the work that comes with introducing new production and changing the product models to produce.

The machine flexibly supports various production for users in a variety of sectors including EMS, automotive industry, and more.

The machine flexibly supports various production for users in a variety of sectors including EMS, automotive industry, and more.

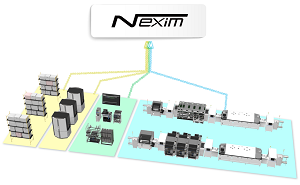

Part management solutions using the integrated production system, Nexim

Highlights

As market needs diversify, mass customization that achieves QCD at the same level as mass production is being required of manufacturing sites. However, in the field of high-mix production in which product models are frequently changed, keeping feeders and parts on the production floor and delays in the work associated with these are issues that need to be addressed.

Here, we will introduce our solutions for parts preparation and management.

Here, we will introduce our solutions for parts preparation and management.

Integrated Production System Nexim

Unified management system for SMT lines. It has functions designed for smart factories, including program creation, work support in each process, and M2M coordination, making it possible to maintain high operation rates and quality.

Advanced Feeder Stand

By linking with the management system, this unit guides operators to the locations of feeders or feeders with parts set on the advanced feeder stand.

With the LED lights that indicate the locations of feeders or feeders with parts set on the advanced feeder stand when they are required for production, this unit supports external changeover work.

With the LED lights that indicate the locations of feeders or feeders with parts set on the advanced feeder stand when they are required for production, this unit supports external changeover work.

Automated Part Warehouse sTower, sTower II

Recently, there is a growing need for automatic part warehouses that can quickly and accurately check out the parts required for production.

sTower series (sTower, sTower ll) can manage parts in various supply packaging and even parts in groups. Linking multiple towers is also possible depending on your intended purpose and installation space. This unit has the versatility to become your ideal automatic part storage system.

sTower series (sTower, sTower ll) can manage parts in various supply packaging and even parts in groups. Linking multiple towers is also possible depending on your intended purpose and installation space. This unit has the versatility to become your ideal automatic part storage system.

Automation solutions for insertion and assembly processes

Highlights

The manual insertion process has been cited as an issue that causes variations in quality and work time, and there is a growing demand for automation.

We have automation solutions for handling parts of a variety of sizes, shapes, and supply types, from leaded parts to large and odd-shaped parts, and addressing issues faced in the insertion process.

We have automation solutions for handling parts of a variety of sizes, shapes, and supply types, from leaded parts to large and odd-shaped parts, and addressing issues faced in the insertion process.

Modular Type Multi-purpose Automated Fabrication Machine SmartFAB sFAB-D

sFAB-D delivers stable quality and productivity by automating manual insertion processes. It has flexible options for handling leaded parts, as well as large, odd-form parts in almost any size, shape, and packaging type.

Auto Inserter sFAB-alpha

This is an all-in-one inserter in which the insertion processes for radial parts, axial parts, and jumpers are merged into one machine. In comparison to lines using linked together dedicated insertion machines, the occupied space is greatly reduced and the initial costs are reduced.

Panel Assembly Robot Cell SW-BA

Equipped with the newly developed SmartWing SCARA robot, this can insert workpieces with leads such as connectors. Workpieces supplied using a variety of packaging methods, such as loose parts and in simple trays, can be used in production without manually changing the packaging method.

-

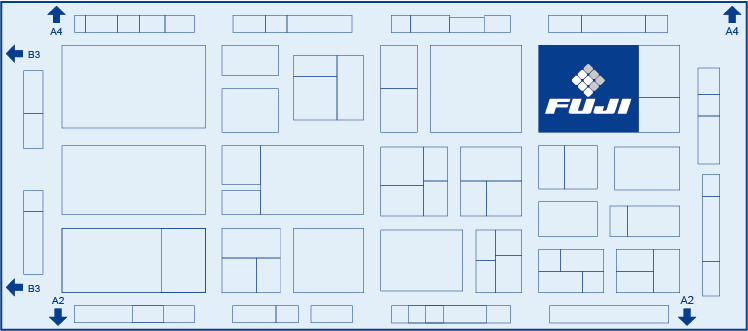

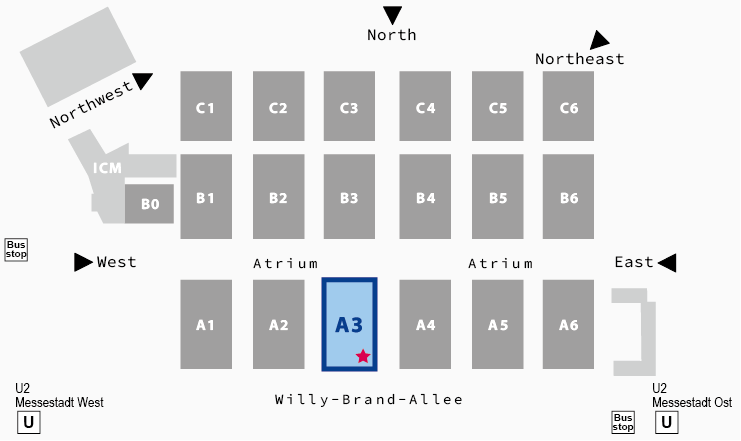

Messe München, overall view

-

A3 hall, booth map